Imaclamp - Tri Clover Gasket

Price 2.60-14 USD ($)/ Pack

MOQ : 6 Bags

Imaclamp - Tri Clover Gasket Specification

- Medium

- Liquids, Gases

- Hardness

- Shore A 605

- Working Temperature

- -40C to +230C

- Standard

- ASME BPE, DIN, ISO

- Temperature Resistance

- Up to 230C

- Gasket Coefficient

- 0.11 (typical)

- Pressure Resistance

- Up to 10 Bar

- Vaccum Range

- Up to 750 mm Hg

- Material

- Silicone / EPDM / PTFE / Viton / Neoprene

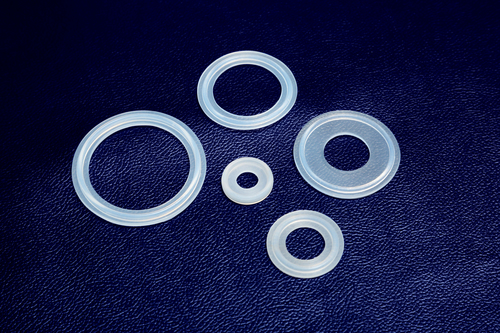

- Shape

- Round

- Size

- 1 inch to 4 inch

- Application

- Pharmaceutical, Food, Chemical Process Industries

- Thickness

- 3 mm

- Reusable

- Yes

- Connection Type

- Tri-Clamp / Tri Clover Fittings

- Odour

- Odourless

- Shelf Life

- 5 Years

- Density

- 1.18 to 2.0 g/cm³ (material dependent)

- Surface Finish

- Smooth

- Colour

- White / Translucent / Black

Imaclamp - Tri Clover Gasket Trade Information

- Minimum Order Quantity

- 6 Bags

- Supply Ability

- 100000 Bags Per Week

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

- Certifications

- Food Grade Certificate Laboratory Test Report USP Class VI Certificate

About Imaclamp - Tri Clover Gasket

Imaclamp - (Silicone/ Viton®/ EPDM):

- Made from Platinum Cured Silicone Rubber

- Conforms to FDA 21 CFR.177.2600

- Conforms to USP Class VI Requirements

- Animal Derived Ingredient Free

- Silicone Tri-Clover Gaskets are available with collar for better grip and also without collar

- Available in Red/Orange/White Transparent colors

Types of Imaclamp :

- T/C Gaskets

- Mesh T/C Gaskets

- PTFE Envelop Gaskets

- Sensor T/C Gaskets

- Validation T/C Gaskets

NOTE: Price vary as per the sizes. Kindly email or call us for best available rate.

High-Performance Compatibility and Safety

Imaclamp Tri Clover Gaskets adhere to industry standards, ensuring safe and leak-proof connections for a wide range of applications. With material options such as Silicone, EPDM, PTFE, Viton, and Neoprene, these gaskets are compatible with various media, including liquids and gases, making them ideal for pharmaceutical, food, and chemical processes where hygiene and reliability are paramount.

Exceptional Durability and Reusability

Designed for repeated use, these gaskets offer long service life and consistent sealing performance, even under fluctuating pressures and high temperatures up to 230C. Their structure withstands compressive forces up to 10 bar, and vacuum up to 750 mm Hg, ensuring operational continuity with minimal maintenance. Odourless and easy to clean, Imaclamp gaskets provide a dependable sealing solution.

FAQs of Imaclamp - Tri Clover Gasket:

Q: How is the Imaclamp Tri Clover Gasket typically installed in processing systems?

A: The Imaclamp Tri Clover Gasket is designed to be placed between two Tri-Clamp or Tri Clover fittings, forming a tight seal when the fittings are clamped together. Its round shape and precise thickness ensure optimal contact, and installation typically requires only basic hand tools with no need for adhesives or lubricants.Q: What industries benefit most from using Imaclamp Tri Clover Gaskets?

A: Industries demanding stringent hygienic standards, such as pharmaceutical, food and beverage, and chemical processing, benefit from Imaclamp gaskets. Their smooth, odourless finish and resistance to a broad range of chemicals make them suitable for applications where contamination control is essential.Q: When should Imaclamp gaskets be replaced during regular maintenance?

A: Although Imaclamp gaskets are reusable and designed for long life, it is advised to inspect them regularly for signs of wear, deformation, or chemical degradation. Under normal service conditions, replacement is generally recommended every five years or sooner if damage is detected.Q: Where can Imaclamp Tri Clover Gaskets be sourced for industrial applications?

A: Imaclamp Tri Clover Gaskets are manufactured, exported, and supplied by producers in India and are accessible through specialized industrial suppliers and authorized distributors globally. Bulk and custom orders can typically be arranged directly with manufacturers.Q: What is the process for cleaning and maintaining Imaclamp gaskets?

A: The gaskets can be cleaned using standard cleaning-in-place (CIP) or sterilize-in-place (SIP) procedures typical in food and pharmaceutical industries. Their smooth, non-porous surfaces allow residue removal with mild detergents or appropriate sanitizing agents, followed by thorough rinsing and drying.Q: How can selecting the appropriate material for an Imaclamp Tri Clover Gasket enhance process safety?

A: Choosing the correct materialSilicone, EPDM, PTFE, Viton, or Neopreneensures chemical compatibility and temperature resistance with the process media. Using an incompatible gasket may compromise seal integrity or introduce contaminants; thus, material selection directly impacts safety and regulatory compliance.Q: What are the key benefits of using Imaclamp Tri Clover Gaskets over traditional gasket types?

A: Imaclamp gaskets offer reusable, reliable seals with excellent chemical and thermal resistance, odourless and smooth surfaces for optimal hygiene, and easy installation. Their compliance with ASME BPE, DIN, and ISO standards makes them a preferred choice where quality and operational safety are crucial.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS